ANSI Z358.1 2014 compliance is essential!

The American National Standard ANSI Z358.1 2014 Emergency Eye Wash and Shower Equipment, when specifying emergency shower and eye wash equipment, is the only reference point.

To download the PDF, Click on yje Image above to receive our Special Offer of $27.00 for the Guide

To download the PDF, Click on yje Image above to receive our Special Offer of $27.00 for the GuideFor the proper selection, installation, and maintenance of emergency shower and eye wash stations, this is the only Standard.

You should review the

ANSI Z358.1 2014 Compliance Standard in detail.

It’s very important to plan.

In an emergency every second counts!

The ANSI Z358.1 standard includes minimum performance, testing, installation, maintenance and training specifications for equipment and systems used for the emergency treatment of the eyes or body of a person who has been exposed to injurious materials.

The ANSI Z358.1 standard includes minimum performance, testing, installation, maintenance and training specifications for equipment and systems used for the emergency treatment of the eyes or body of a person who has been exposed to injurious materials.

Each section of the ANSI Z358.1 Standard addresses how the equipment should perform, as well as the testing procedures to ensure proper operation, installation, maintenance and training.

ANSI Z358.1 2014 compliance covers plumbed and self-contained emergency showers and emergency eyewash equipment, eye and face wash equipment, combination units, personal wash units, and hand-held drench hoses. These systems are found in manufacturing facilities, construction sites, laboratories, medical offices and other workplaces.

Separate guidelines within the ANSI Z358.1 2014 compliance

There are separate guidelines within the ANSI Z358.1 2014 compliance Standard for eye washes and eye/face washes. An eye wash only flushes the person’s eyes whereas an eye/face wash flushes the person’s eyes and face simultaneously.

In addition, although drench hoses are not allowed to replace a drench shower, the 2009 version does allow these hoses as a replacement for an eye wash or combination eye/face wash as long as the drench hose meets the appropriate requirements.

Non-Compliance with ANSI Z358.1 2014

Fines and Litigation

American National Standards Institute (ANSI)

The American National Standards Institute (ANSI) has specific guidelines, that cover emergency response equipment including emergency showers and eye washes. This body has, in the form of operating standards, regulatory safeguards, and procedures.

To comply with the law and be ANSI Z358.1 2014 compliant, three significant changes are now immediately required….

Most companies have the wrong water temperature and are not compliant.

If you have a combination shower and eye wash then you need to know the simultaneous use and the minimum flow rate requirements.

Testing requirements and how to stay compliant are now major considerations.

For example, the ANSI Z358.1 2004 compliance revision had a general requirement that flushing fluid be “tepid” which was a bit vague and which led to individual interpretations of the term.

However, in its revised ANSI Z358.1 2014 compliance standard, ANSI clarified the definition of the word “tepid” ” to be in the range of 60 degrees F to below 100 degrees F.

The output flushing fluid must be within that range immediately at the start-up of the equipment and remain there throughout the full 15-minute use cycle. Generally, temperatures higher than 100 degrees F may cause chemical interactions with the skin and result in further damage. At 60 degrees F and below hypothermia becomes a concern.

It is important to realize that a very specific requirement is now in place. If ANSI Z358.1 2014 compliance is delayed you may have fines levied by OSHA for non-compliance to ANSI and other standards. It’s possible that these fines could be substantial.

Not only that, it’s also possible that the temperature range requirement could result in a case of negligence in a lawsuit filed by an injured employee. For example, if the emergency shower water was too cold. The employee may be unable to stand under the shower for the full required period which results in the employee receiving a greater injury.

DISCOVER Critical Information on WHAT’S REQUIRED for emergency shower and eye wash compliance HERE

2024 – 2025 © Copyright – All Rights Reserved

![]() The time will come when you may have to choose an emergency eye wash manufacturer and/or an emergency shower equipment manufacturer. When that time does come then you’ll want a manufacturer whose products consistently meet ANSI Z358.1 2009 performance requirements. In this regard, we suggest you check out Speakman Emergency Showers. They manufacture a full range of emergency showers, eye washes, and eye/face washes.

The time will come when you may have to choose an emergency eye wash manufacturer and/or an emergency shower equipment manufacturer. When that time does come then you’ll want a manufacturer whose products consistently meet ANSI Z358.1 2009 performance requirements. In this regard, we suggest you check out Speakman Emergency Showers. They manufacture a full range of emergency showers, eye washes, and eye/face washes. Also, click here for emergency eyewash manufacturers:

Also, click here for emergency eyewash manufacturers: All of its deluge equipment is designed and manufactured in its Sydney plant. Its deluge showers are internationally recognized with installations in France, Russia, Indonesia, Malaysia, Singapore, Turkey, China, and in the Middle East, South America, West Africa, and other places. They stand ready to perform their lifesaving services.

All of its deluge equipment is designed and manufactured in its Sydney plant. Its deluge showers are internationally recognized with installations in France, Russia, Indonesia, Malaysia, Singapore, Turkey, China, and in the Middle East, South America, West Africa, and other places. They stand ready to perform their lifesaving services.

The Comfortcool™ Principle:

The Comfortcool™ Principle:

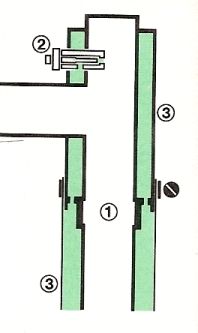

The supply of water is held static in the supply tube (1). A needle valve (2) allows water from the supply tube to enter the jacket (3) from which it percolates to the outside surface and evaporates to the atmosphere. This avoids wastage of water when, to maintain cool conditions, it is allowed to trickle from the system or discharge regularly under temperature control. Also, this overcomes the dangerous and avoidable time delay encountered when dry pipe showers are employed.

The supply of water is held static in the supply tube (1). A needle valve (2) allows water from the supply tube to enter the jacket (3) from which it percolates to the outside surface and evaporates to the atmosphere. This avoids wastage of water when, to maintain cool conditions, it is allowed to trickle from the system or discharge regularly under temperature control. Also, this overcomes the dangerous and avoidable time delay encountered when dry pipe showers are employed.